WHAT HAPPENED DURING THE RESEARCH AND DEVELOPMENT PHASE?

MS — “We rang a lot of doorbells of suppliers who used the same materials and techniques to produce wine vats or sporting goods, but unfortunately they were not willing to collaborate on this experimental research. But we were not discouraged, and we continued to search until we found an entrepreneur who also worked with this material for his own, personal pursuits (he had built a motorized hang-glider). He was enthusiastic about the project and immediately wanted to cooperate on it. He had a company that produces extraordinary, very special fishing rods, but he decided to take the leap with us into the world of lighting. He sent us trial samples, which he made on his own, asking our opinion on new resins and new threads. Design is made by people who act and interact, together. This is a totally Italian kind of magic. In the rest of the world, companies often wait for the designer to arrive, like a superhero, ready to deliver something that is already done, ready for implementation. But that is not how it works: to make truly innovative projects, there has to be on-going dialogue, a process where problems arise and are solved together. I prefer that way of working.”

DID YOU MAKE MODELS AND PROTOTYPES FOR STUDY?

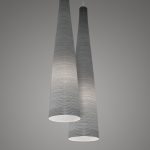

MS — “The first model was made with a traditional closed mould, but then it occurred to us that we could try another technique – “rowing” – based on the wrapping of threads around a full volume. Observing the threads that could be used, I found some bundles that were considered defective, where the thread was not perfectly linear, but seemed a little vibrated. This type of thread became the resource for the final production. The fibres are not all uniform: we wanted to utilize this “defect” which makes each lamp have a unique quality. We wanted to get away from the technical aspect, to bring the value of craftsmanship and a warm sense of material back into play, which is something people know how to do in Italy.” In an initial prototype, I had cut off the top at a 45° angle, inserting a car headlight. If I look at that first prototype again today it bothers me a little, but that’s absolutely normal because it represents the beginning of a long search path. To reach a simple product, a lot of work is required. At first, my sign was too strong, almost violent. Foscarini was very good at mediating it, and that’s just right, that’s what design is all about. It means striking the right balance between the parties on the field to work together on a common endeavour. Only by working with Foscarini, who knows how to treat light, who knows how to add taste to transparencies and warmth to texture, were we successful in making sure the product achieved its proper proportion and authenticity. We managed to get a much cleaner, clear-cut object, so the important thing is the light it produces, the transparency of the body and the vibration that can be seen in its design. Not an object that screams out loud, but rather a gentle element that glides into homes.”

WHAT ARE THE SPECIFIC CHALLENGES IN A PROJECT INVOLVING LIGHT?

MS — “After this lamp and after this approach to composite materials, I got back to some extent to the label of the designer who makes lamps with novel materials. This doesn’t bother me, and in fact it is what we love doing, together with Foscarini. So today, if in my research I find something interesting, or something that has not yet been utilized in the world of lighting, Foscarini is the company with which I can have the best chance of developing something original and innovative.”

WHAT ARE THE MOST IMPORTANT ASPECTS OF THE LIGHTING TECHNOLOGY USED IN THIS PROJECT?

MS — “Over the last 20 years, lighting technology has evolved a great deal, and now we use LEDs. With respect to the technology of the past, it is a bit like the difference between electronic injection and a carburettor. You could achieve excellent results with a carburettor, but it took a genius who knew how to listen to motors, and how to tune them by hand. For Mite something similar happened. In the first version we inserted a rather long light bulb, positioned at a certain height. To close the trunk, we shaped a circular chrome-finished metal plate, experimenting with ifferent angles, to reflect the direct light upward but also to make the light go down in the body of the lamp, letting it run over the material, with a back-lighting effect. Obviously that technology created limits of freedom of action, while today with LEDs we can take the luminous effect wherever we want it.”

HOW HAS THE WORK OF DESIGNERS CHANGED DURING THESE FIRST TWO DECADES OF THE NEW MILLENNIUM?

MS — “I am happy with my work today because its seems like a return to the 1970s, when the entrepreneur had an important role and expressed clear intentions made of objectives, a schedule, the right budget, and knowing that he had worked well up to that point, wanted to go further, somewhere he had never gone before. Perhaps it is this very arduous moment of the pandemic, perhaps it is because I am starting to get tired of working with large multinational and oriental corporations, but I think the time has come to get back to direct, personal work with entrepreneurs.”